Motosikal naked kelas terbuka menengahkan falsafah agresif, gaya, dan prestasi. Dalam erti kata lain, motosikal yang tulen. Memang benar, kita bertuah kerana mempunyai banyak motosikal naked kelas terbuka (1000cc ke atas) di Malaysia, tetapi tawaran motosikal Jepun seolah-olah ketinggalan berbanding pesaing Eropah dalam minda pengguna. Jadi, adakah Honda CB1000 SP (2025) ini akan mengubah persepsi ini?

Apakah itu Honda CB1000 SP (2025)?

Pertama sekali, CB1000 juga dikenali sebagai Hornet 1000 di pasaran Eropah, jadi kita perlu huraikan dengan lebih lanjut.

Siri CB1000 merangkumi motosikal sekmen naked/roadster kelas terbuka Honda, dan kini ia mempunyai dua model utama, iaitu CB1000 dan CB1000R. Sebuah prototaip CB1000F turut didedahkan di Tokyo Motorcycle Show pada Mac lalu dan mungkin akan dilancarkan pada perlumbaan ketahanan Suzuka 8 Hours bulan Ogos nanti.

CB1000R: Honda menggelarnya sebagai sebuah streetfighter Neo Café, dengan lengan ayun sebelah.

CB1000F: Varian terbaharu ini merupakan penghormatan kepada CB750F/CB900F yang ditunggang oleh Freddie Spencer dalam Kejuaraan AMA Superbike pada akhir 70-an dan awal 80-an.

CB1000/CB1000 SP/Hornet 1000: Sebagai sebuah streetfighter yang sporty dengan lengan ayun (swingarm) berkembar konvensional. Versi SP ini pula dilengkapi pelbagai kelengkapan premium.

Ketiga-tiga varian ini berkongsi enjin 1000cc, empat silinder sebaris (inline-four) yang diambil daripada Honda CBR1000RR Fireblade 2017, namun ditala untuk tork kuat pada RPM rendah ke sederhana, serta rangka tiub keluli.

Untuk memahami falsafah CB1000 dengan lebih mendalam, nama Hornet sangat penting dalam sejarah Honda. Pengeluar ini melancarkan CB600F Hornet pertama pada tahun 1998 untuk pasaran Eropah. Ia dikuasakan oleh enjin 599cc, empat silinder sebarisyang diambil daripada motosikal sport CBR600F (dan kemudiannya CBR600RR), tetapi tanpa komponen prestasi tinggi.

Hasilnya, Hornet menjadi lebih mudah dimiliki, praktikal, dan lebih murah, sekaligus menjadi motosikal 600cc paling popular di UK dan Eropah.

Kembali kepada CB1000/Hornet 1000, ia mewakili semangat prestasi yang mudah dicapai, praktikal, pada harga yang berpatutan, dan dilitupi reka bentuk badan yang tajam dan agresif. Ini memberikan ciri khas berbanding model-model lain dalam keluarga CB1000.

Ciri-ciri utama Honda CB1000 SP (2025)

- Enjin 1000cc, disejukan cecair, 16 injap, DOHC, empat silinder sebaris yang menghasilkan kuasa maksimum 155 hp (115.6kW) pada 11,000 RPM dan tork maksimum 107 Nm pada 9,000 RPM.

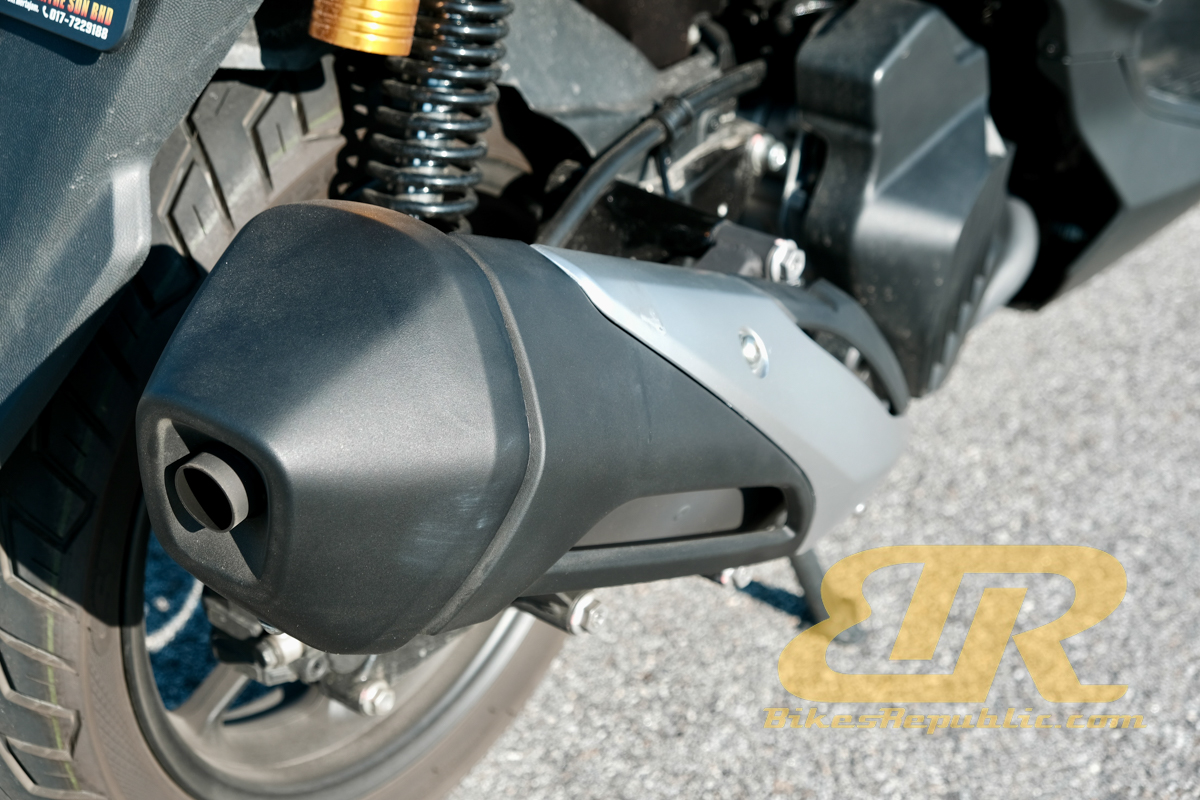

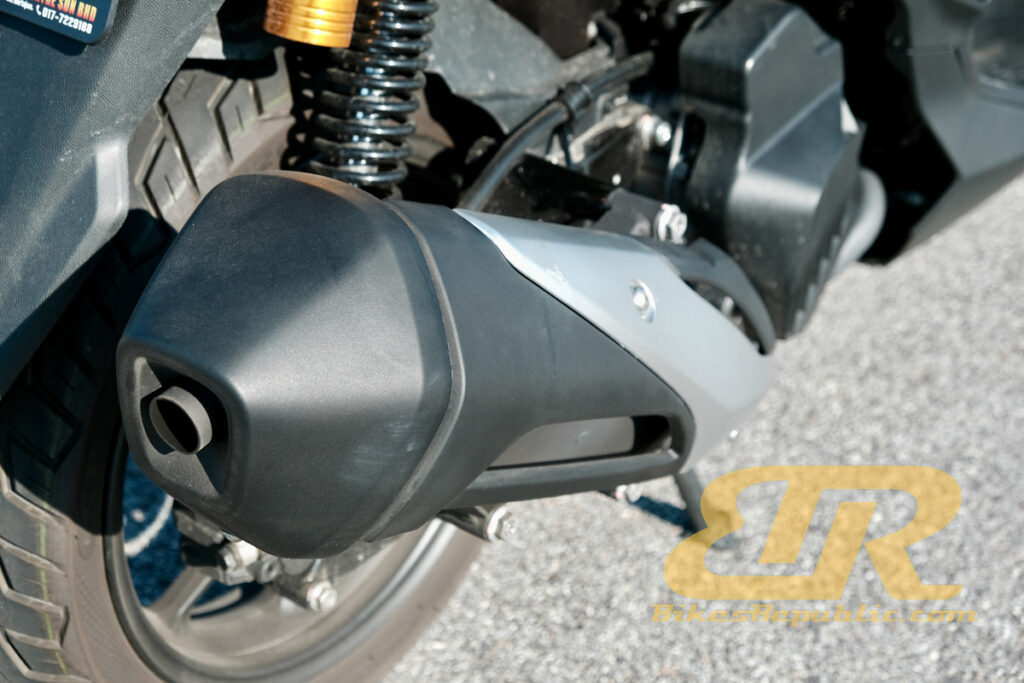

- Varian SP ini mendapat peningkatan 5.4 hp (4 kW) dan 2 Nm dengan penggunaan injap ekzos Revolutionary Controlled (RC) yang dipasangkan pada tiub ekzos.

- Sistem penghantaran petrol dikawal oleh PGM-FI (Programmed Fuel Injection), dan tangki minyak 17 liter.

- Klac plet berganda dengan ciri bantuan dan slipper, transmisi 6 kelajuan.

- Quickshifter untuk penukaran gear tanpa menggunakan tuil klac yang boleh dilaras.

- Lampu LED berganda dan tangki yang berbentuk agresif.

- Rangka keluli jenis twin-spar.

- Fork hadapan Showa SFF-BP 41mm boleh laras sepenuhnya.

- Monoshok belakang Öhlins TTX36 boleh laras sepenuhnya dengan sistem Pro-Link.

- Kaliper brek depan Brembo Stylema dengan cakera apung 310mm.

- Skrin TFT 5 inci dengan Honda RoadSync menyokong panggilan, muzik, navigasi dan notifikasi melalui Bluetooth.

- Sistem Emergency Stop Signal (ESS) yang menyalakan lampu kecemasan semasa brek mengejut untuk keselamatan tambahan.

- Tiga mod tunggangan (SPORT, STANDARD, RAIN) ditambah dua mod USER yang boleh disesuaikan.

- Mod USER1 dan USER2 membolehkan penunggang menyesuaikan kuasa enjin, tindakbalas pendikt, dan brek enjin.

- Sistem Honda Selectable Torque Control (HSTC) empat peringkat dan Kawalan Wheelie meningkatkan cengkaman dan kestabilan dalam pelbagai keadaan.

- Berat kering 211 kg.

Menunggang Honda CB1000 SP (2025)

Pra-tunggangan

Pandangan pertama kami terhadap CB1000 SP yang baharu, dengan enjin yang bergemuruh bila ia hidup dan habanya yang dirasai oleh kami, membuatkan degupan jantung kami semakin laju. Kami pernah menunggang CB1000R beberapa tahun lepas, tetapi atas sebab tertentu, ia tidak memberikan kesan yang sama…

Motosikal baharu ini mempunyai bahagian depan yang lebih tajam (yang memang menimbulkan pelbagai pendapat), tangki minyak yang besar, dan ekor yang runcing. Rim dan fork berwarna emas mengimbangi warna badan hitam matte yang mirip pesawat stealth, menghasilkan penampilan mewah seperti motosikal dan kereta lumba era 70-an.

Berkenaan bahagian depannya, kami berjumpa komen yang mengatakan ia serupa atau bahkan mirip Kawasaki Z1000 dan Ducati Streetfighter. Namun, apa yang boleh kami katakan ialah ia kelihatan jauh berbeza secara langsung.

Kami selalu memulakan ujian tunggangan pertama dengan membiasakan diri dengan kawalan dan tetapan motosikal, bagi mengelakkan kekeliruan dan gangguan semasa menunggang nanti.

Panel TFT 5 inci ini sama dengan yang terdapat pada skuter NSS250 yang baru kami hantar kembali tadi, dan ia amat dialu-alukan kerana paparan warnanya yang tajam dan hidup. Setiap ikon, nombor, dan grafik mudah dilihat dan difahami. Untuk menelusuri data dan ciri-ciri, kami menggunakan “joystick” yang terletak pada handel sebelah kiri.

Jadi, kami memasangkan peranti Bluetooth dengan menambah motosikal baharu dalam Aplikasi Honda RoadSync, menyesuaikan tetapan paparan, memilih mod tunggangan, serta menetapkan mod quickshifter melalui skrin TFT tersebut.

CB1000 bukan sahaja menggunakan skrin TFT yang sama, malah perisiannya juga serupa dengan NSS250. Kami rasa ini satu perkara yang baik kerana ia memudahkan konfigurasi semua motosikal Honda di garaj anda. (Dalam mimpi paling indah kami lah, berdasarkan pendapatan kami sekarang.)

Tunggangan pertama

Mula-mula sekali, kami mendapati ketinggian tempat duduknya agak rendah. Ya, ia kelihatan tinggi dalam gambar mahupun secara langsung, tetapi kami boleh meletakkan kedua-dua kaki di tanah dengan stabil. Honda menyenaraikan ketinggian tempat duduk hanya pada 810mm, berbanding kebanyakan motosikal naked kelas terbuka lain yang biasanya sekitar 830mm.

Faktor yang membantu ialah bahagian ‘pinggang’ motosikal yang ramping di mana tempat duduk dan tangki minyak bertemu. Profil depan tangkinya lebar, menirus di bahagian tengah, kemudian melebar kembali di tempat duduk penumpang yang memberikan bentuk seperti tebuan (hornet) apabila dilihat dari atas.

Kami memulakan perjalanan dalam mod STANDARD, dan motosikal ini dengan jelas menunjukkan ia ditala untuk prestasi agresif. Melepaskan klac pada gear pertama dan membuka sedikit pendikit sudah cukup untuk membuatkannya mengaum laju di jalan. Sungguh menyeronokkan kerana ia meninggalkan semua kenderaan lain ketika berlepas dari lampu isyarat, ditambah dengan bunyi ekzos yang mengejutkan kuat untuk unit yang “ori.”

Tunggangan harian

Walaupun kami sangat menggemari tork pada RPM rendah dan sederhana yang memberikannya karakter lebih mirip enjin tiga silinder berbanding enjin segaris-empat tradisional, jelas terasa enjin ini sangat ‘bersemangat’ untuk meluncur. Ketika cuba membelah lorong pada kelajuan rendah dalam mod STANDARD, motosikal terus meluru ke depan walaupun pendikit dibuka sedikit, manakala penutupan pendikit sedikit sahaja menghasilkan kesan brek enjin yang kuat.

Kami cuba mengurangkan lagi kesan brek enjin melalui mod USER1 dan USER2, namun tidak berhasil. Akhirnya, kami lebih kerap menggunakan klac untuk kawalan yang lebih halus.

Tidak lama kemudian, kami mendapati mod RAIN merupakan pilihan terbaik untuk mengharungi kesesakan lalu lintas. Apabila ditukar ke mod ini, enjin menjadi lebih senyap dari segi bunyi, sementara respons pendikit dan brek enjin menjadi lancar.

Namun jangan salah faham – CB1000 tetap sangat menyeronokkan untuk ditunggang dengan laju di kawasan bandar, terutamanya memandangkan kita mempunyai begitu banyak selekoh menaikki dan menuruni lebuh raya!

Menunggang ke atas “Gunung”

“Gunung itu” menjadi laluan ujian rutin kami kerana ia menawarkan segala yang ada dalam sistem jalan raya Malaysia: Liku-liku lebar di lebuh raya, selekoh tajam, dan tidak rata semasa mendaki dan menurun.

Kami bertukar ke mod SPORT sebelum meninggalkan stesen minyak BHP Gombak. Bunyi enjin kini seolah-olah membakar bahan bakar roket – lebih kuat, lebih garang, dan lebih menggetarkan – bahkan sebelum kami mula bergerak.

Sebaik saja meninggalkan kawasan stesen minyak dan menuju ke lebuh raya, tangan kami ditarik lurus sepenuhnya apabila enjin memberikan tendangan kuasa yang kuat – sehingga handel terasa ringan dan mula bergoyang. Kami bersyukur sistem HSTC dilengkapi dengan Kawalan Wheelie, dan boleh mendengar enjin sedikit terencat seperti klac yang dilepaskan perlahan. Jika tidak, mungkin kami sudah melakukan wheelie dalam keadaan tidak terkawal.

Syukurlah juga, sistem suspensi dan rangka motosikal ini mampu menangani situasi sedemikian walaupun kelihatan sederhana. Di lebuh raya, stereng yang tajam membolehkannya mencapai setiap titik yang kami tuju tanpa ragu-ragu atau masalah. Kami boleh mengubah laluan di selekoh walaupun dalam keadaan condong ekstrem, tanpa rangka dan tayar menunjukkan sebarang masalah. Bonggolan di lebuh raya langsung tidak terasa. Satu-satunya kesukaran adalah untuk berpaut kerana tiupan angin yang kuat pada kelajuan tinggi.

Ketika mendaki, kami masukki setiap selekoh tanpa memperdulikan jejari atau bentuk selekoh, dan membiarkan tork enjin memecutkan kami ke selekoh berikutnya. Namun begitu, suspensi – terutamanya shock belakang – terasa lebih keras ketika menghadapi lubang atau bonjolan besar. Tiga klik pengurangan untuk redaman lantunan monoshok TTX36 tersebut menyelesaikan masalah itu. Selepas itu, tiada lagi bonjolan yang mengganggu garis kami di selekoh.

Sistem brek juga luar biasa. Ia memberikan kuasa berhenti yang mengagumkan disertai perasaan yang sempurna pada tuas. Dalam situasi genting, perasaan ini membolehkan kami melakukan trail braking masuk ke selekoh – cukup untuk mengejutkan beberapa penunggang motosikal supersport!

Satu lagi ciri menambah sensasi menunggang motosikal ini ialah injap ekzos RC yang mula terbuka pada 5,700 RPM. Apabila menunggang di bawah paras ini, kami mendengar deruman ekzos yang dalam. Namun begitu, apabila mencapai 5,700 RPM dan ke atas, bunyi ekzos bertukar menjadi deruan yang membuatkan bulu roma di tengkuk kami berdiri!

Namun perlu diingat, 5,700 RPM pada gear keenam bermaksud motosikal ini sudah meluncur melebihi 130 km/j…

Tiba-tiba kami tersedar betapa mudahnya kami boleh bercanggah dengan pendapats endiri. Penguji ini pernah berkata bahawa menunggang motosikal atau skuter yang lebih perlahan itu menenangkan, dan mempersoalkan kenapa perlunya motosikal berkuasa tinggi – hanya untuk kemudian terkekek-kekek dalam helmet seperti budak sekolah apabila Honda CB1000 SP ini meninggalkan semua yang lain.

Konklusi

Honda CB1000 SP (2025) mengingatkan kami bahawa motosikal berkuasa tinggi tetapi mudah dikawal sentiasa menggembirakan untuk ditunggang. Inilah jenis motosikal yang membuatkan anda ingin keluar dan terus menunggang. Dan menunggang.

Semestinya, motosikal ini tidaklah sempurna sepenuhnya kerana respons pendikit yang agak mendadak dalam beberapa mod menunggang – tapi kami berjaya menyesuaikan diri dalam beberapa minit pertama. Namun, karakter sebegini yang memberikan dua personaliti berbeza: seperti kucing manja (tetapi lincah) dan harimau, bergantung pada pilihan dan mood anda.

Selain itu, peralihan gear naik menggunakan quickshifter tidak begitu lancar pada tiga gear pertama walaupun kami sudah mencuba pelbagai RPM, mod, dan tetapan. Tapi apa masalahnya? Kami tetap gemar menukar gear secara manual pada setiap motosikal (skuter tidaklah, ya!).

Dengan harga hanya RM69,999 (harga jualan, bukan atas jalan), Boon Siew Honda sekali lagi membawa sebuah motosikal pemenang – dan ya, ia mampu menyaingi motosikal Eropah dengan menawarkan kawalan hebat dan kebolehcapaian yang baik.

Nasihat terakhir kami: Jangan cuba uji motosikal ini melainkan anda bersedia mengalami ketagihan yang menjangkiti kami!

Spesifikasi Honda CB1000 SP (2025)

| Model |

CB1000 Hornet SP |

| Enjin |

|

| Jenis |

1,000cc, sejukan cecair, condong 27.6º, empat silinder sebaris, empat lejang |

| Sistem injap |

DOHC; 4 injap setiap silinder |

| Gerek x Lejang |

76.0mm x 55.1mm |

| Nisbah mampatan |

11.7:1 |

| Sistem bahan api |

Suntikan bahan api PGM-FI dengan badan pendikit 44mm (pendikit ride by wire) |

| Pencucuhan |

Transistor penuh |

| Penghidup |

Elektrik |

| Transmisi |

6 kelajuan, manual |

| Klac |

Basah, plet berganda |

| Pacuan akhir |

Rantai #525; 15T/45T |

| SUSPENSI |

|

| Depan |

Fork Showa Separate Function Front Fork Big Piston (SFF-BP) 41mm dengan larasan prabeban, serta redaman mampatan dan lantunan. |

| Belakang |

Sistem Pro-link dengan penyerap hentakan Öhlins TTX36 yang boleh dilaras prabeban, serta redaman mampatan dan lantunan. |

| BREK |

|

| Depan |

Kaliper Brembo Stylema berkembar dengan cakera 310 mm; ABS |

| Belakang |

Kaliper Nissin satu piston tunggal dengan cakera 240mm; ABS |

| TAYAR |

|

| Depan |

120/70-17 |

| Belakang |

180/55-17 |

| DIMENSI |

|

| Sudut stereng |

25º |

| Jejak |

98 mm |

| Panjang |

2141 mm |

| Lebar |

792 mm |

| Tinggi |

1087 mm |

| Kelegaan bumi |

135 mm |

| Ketinggian pelana |

810 mm |

| Jarak antara gandar |

1455 mm |

| Kapasiti petrol |

17 liter (termasuk rizab 3.8 liter) |

| Berat basah |

211 kg |

| WARNA |

|

| Warna |

Matte Black Metallic |

Galeri gambar