The star of the of show during our visit to SYM in Taiwan was undoubtedly the the SYM ADXTG, but we were also given the opportunity to sample another model: the SYM TTLBT 508.

Sure, we do not see many GT (Grand Touring) scooters in Malaysia, most probably to their pricing, but there is demand for them. These machines slot in nicely between automatic scooters and full-sized tourers, thus providing the best of both worlds.

What is the SYM TTLBT 508?

It is a grand touring maxi scooter, whose predecessor was the SYM MAXSYM 500. Grand touring means luxury and the TTLBT has it all.

By the way, “BT” is the factory’s code for the new “Bestia” (in Italian or “Beast”) touring series, while TTL stands for “Tartaruga” in Italian or “Turtle.” No, that does not denote that bike is slow but the turtle holds a significant place in Chinese culture, which alludes to symbols of longevity, power, and tenacity, and are often associated with good luck and prosperity.

Highlights:

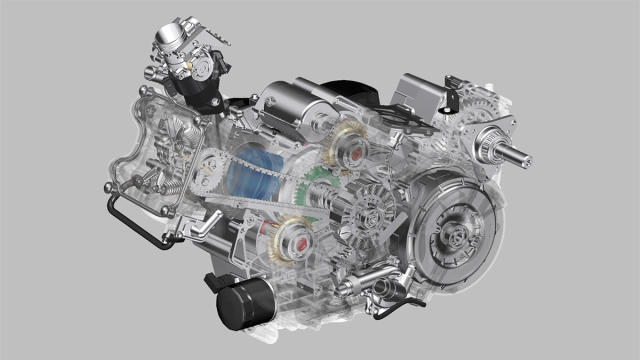

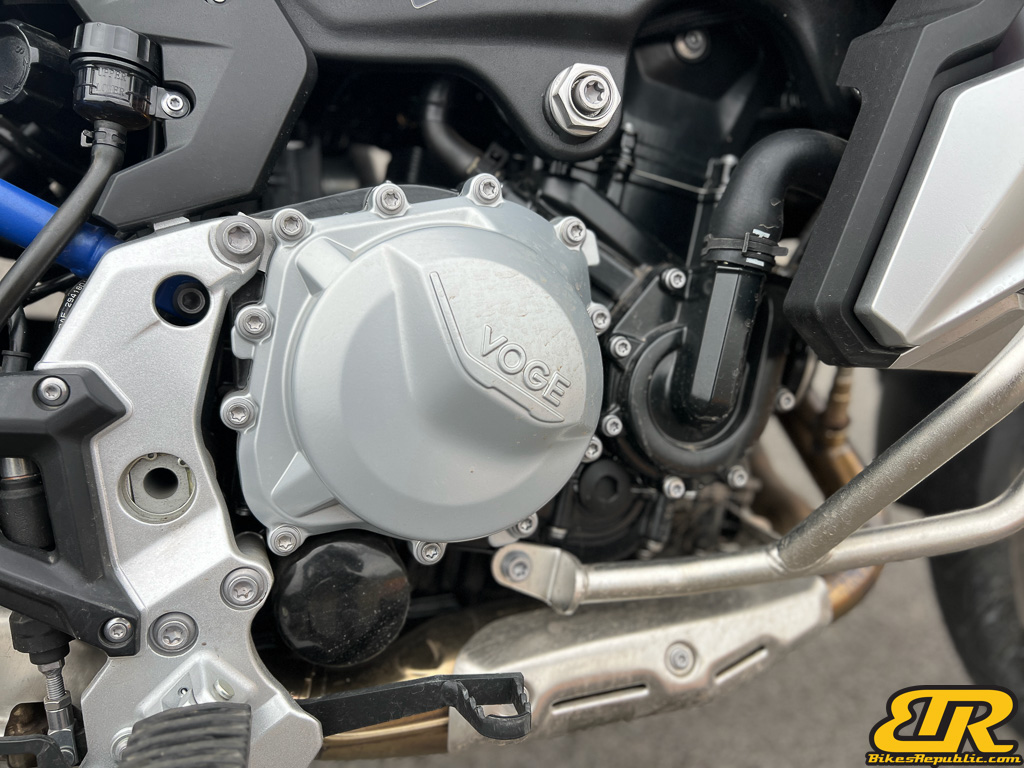

- 508cc, DOHC, 8-valve, liquid-cooled, parallel-twin engine which produces 44.9 HP (33.5 kW) at 6,750 RPM and 49.9 Nm at 5,250 RPM.

- Notice that the torque is higher than maximum power? It shows that the bike is good for carrying a passenger and hauling cargo – great attributes for a tourer.

- Front suspension consists of upside-down forks, while the rear has a side-mounted monoshock with multi-link.

- Front brakes consist of dual 275mm discs gripped by dual four-piston calipers, while the back wheel has an equally sized 275mm.

- The brakes are supported by dual-channel ABS.

- The throttle is ride-by-wire, enabling ride modes which are paired to the traction control system (TCS).

- Riding modes are: “Normal with TCS,” “Normal without TCS,” and “Rain with TCS.”

- The traction control system receives input from an inertial measurement unit in order to provide the best strategies, especially during cornering.

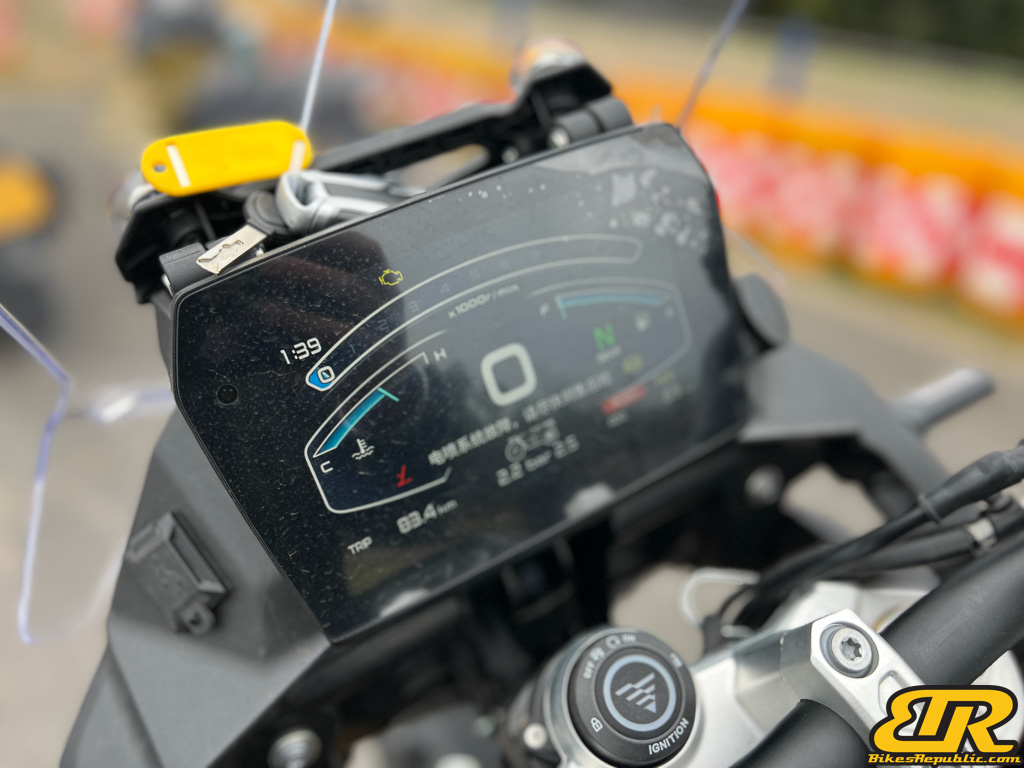

- 7-inch TFT display with Apple Carplay funtions.

- Cruise control which can be activated when speeds are above 50 km/h.

- Electrically-adjustable windshield.

- 37-litre under seat storage compartment, along with two detachable panniers, each with 14.4 and 13.6 litres of space.

- Heated grips with 4 levels of power.

- 708mm seat height.

- 16-litre fuel tank.

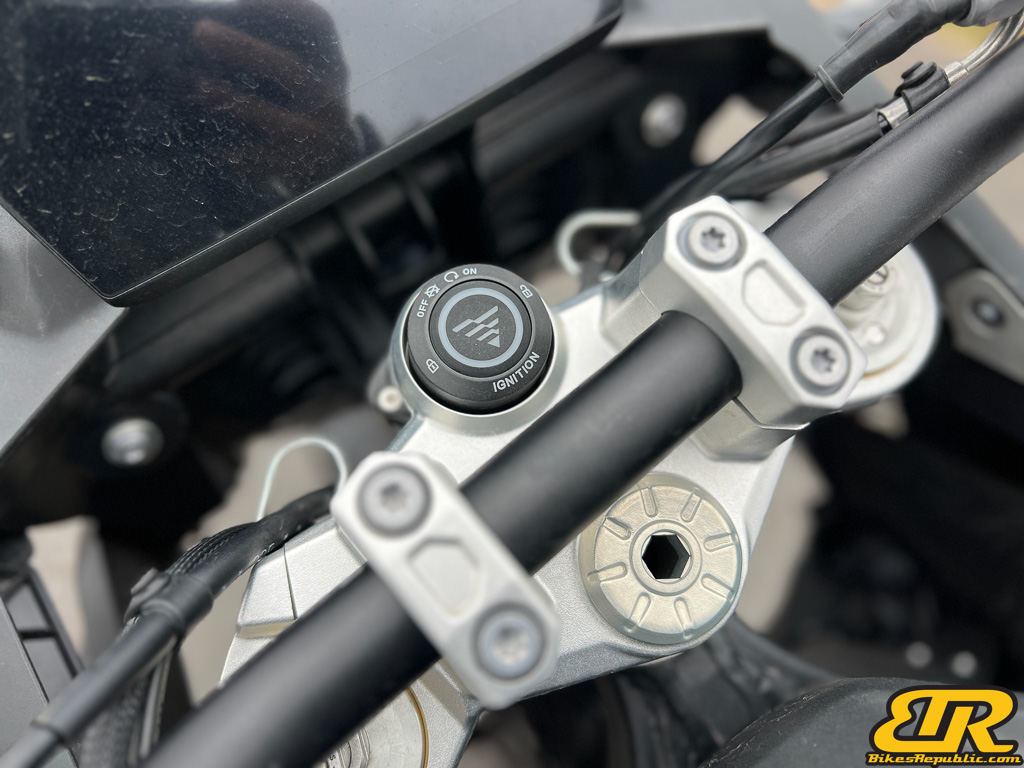

- Advanced Smart Key System.

Those specifications would be the norm for high-end motorcycles, but remember, this is a scooter.

Test riding the SYM TTLBT 508

As with the ADXTG 400, we tested the TTLBT 508 on the same testing ground, which was divided into two areas – a straight section for acceleration and top speed testing, another for manoeuvrability.

Pre-ride

First visual impression says that the TTLBT looks large overall. The front is wide and tall, the body is long, and the seat is wide and thick. This writer was frankly a little intimidated as scooters with wide seats and floorboards cause a little bother with his short legs. (Read: Having to tip toe. This writer is 167cm in height and has short arms and legs.)

However, the TTLBT proves that the adage “never judge a book by its cover” is true. Swinging a leg over the bike was easy without the shoes contacting the rear seat and top of the pannier. Lifting it off its sidestand was easy, meaning that its weight is well-distributed, and putting a foot down flat on the ground was also easy, without needing us to slide a cheek off the seat, unlike other maxi scooters. Pushing it around while seated was also as easy as the smaller ADXTG. We forgot all about this concern immediately, and started playing with er… evaluating other aspects of the bike.

We definitely loved that giant TFT screen. The layout made a lot of sense and the speedometer featured prominently along with the bars of the tachometer. Other functions were placed on the right side of the screen and this writer’s old eyes could pick them out with a single glance. The screen was also sharp without fuzzy edges around the icons and numbers.

Playing around with the Apple Carplay function took some practice but it did not require the deft hands of a Gen-Alpha gamer. It took almost no time to pair to our iPhone (Apple after all), but also to ahem, non-iPhones. It was also easy to hook up our Midland Bluetooth headset.

Riding the TTLBT 508

Okay, okay, with all that out of the way, it is time to ride.

We thumbed the started button and the engine came on with a beautiful low vroom, before settling down to a low booming idle. It sounded a lot like a Boxer boom, instead of that pop-pop-pop of a parallel-twin. Unfortunately, we forgot to ask SYM whether the engine has a 360° crank (both pistons rising and falling simultaneously hence the Boxer-like sound), or 270º crank (mimics the 90º V-Twin), or the typical 180° crank (one piston hits TDC, while the other hits BDC).

Straight-line testing

In any case, the bike rolled ahead easily with the application of the throttle without a sudden jerk or that clutch slip feel of most scooters.

And it was easy to manoeuvre to u-turn despite its length.

So, at the end of the straight, we gave it full throttle for the acceleration test and of course, the engine responded immediately. Not a huge kick, mind you, but a nice, smooth and quick acceleration off the line.

There was also a noticeable lack of rear end squat during hard acceleration, thanks to the long wheelbase and multi-linked suspension.

We applied the brakes from around 140 km/h around the 50m mark and the bike slowed immediately, showing just how effective the brakes were. No drama.

We did the same straight-line test over and over again, yielding the same results, and without fear of frying the clutch unlike on clutched bikes.

Manoeuvrability testing

By now, we have completely forgotten about the SYM TTLBT 508’s size.

So, into the “roundabout”, the bike’s dynamics began feeling like a normal motorcycle, instead of a scooter. It felt so natural. Certain scooters will remind you that it is a scooter and need to be hustled in ways unique to that type of motorcycle, but not the TTLBT. We went into the circle, countersteered and the bike steered around the circle. In fact, it was very keen to steer deeper into the corner, rather than try to go straight, courtesy of those 15-inch wheels.

Now, having ridden many scooters in the past taught us the lesson that their chassis can isolate the feel of what the tyres are doing. In other words, the bike was already sliding down the road on its side while we were still wondering if we had just crashed.

But not so on the TTLBT. Tyre feedback is what gives the rider the confidence. Thus, we went faster and faster around and around, the bike leaning further and further over despite the dusty road surface.

In fact, another tester went even faster around the testing area and he did not reduce his pace when it began raining.

Conclusion

Of course, we need more comprehensive testing of the SYM TTLBT 508 and the SYM ADXTG 400, but we still came away impressed. We tried to find something to complain about the bike for a more rounded review but could not find even one. Again, it was testament to how much development time SYM was willing to put into their products without submitting to the pressure from the competition churning out new model almost at will.

We cannot wait until the bike gets here!