Yamaha made big waves back in 2009 when they introduced the YZF-R1 of that year with a “crossplane engine.” It is also known as the CP4 in short for “crossplane four cylinder.” Yes, it has been 15 years already, yet there still exists some confusion on what it actually means.

Not helping to clear the air is Yamaha calling their parallel-twin CP2 (MT-07, Tenere 700, and YZF-R7) and their triple CP3 (MT-09, Tracer/Tracer GT, YZF-R9).

So, let us take a closer look as to what a “crossplane engine” actually means.

Let us start with the “flat plane” engine

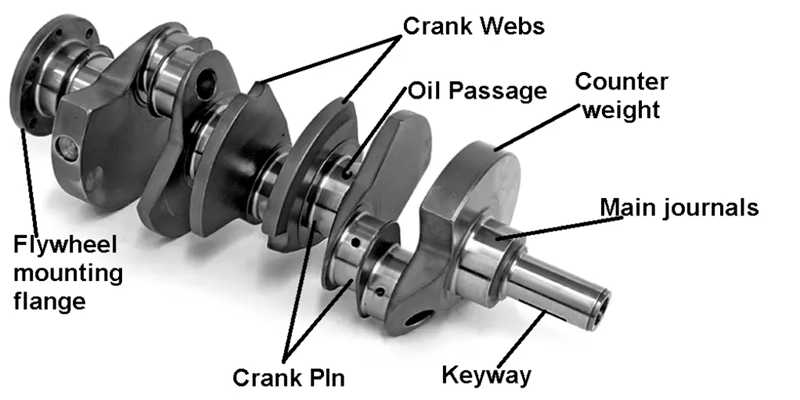

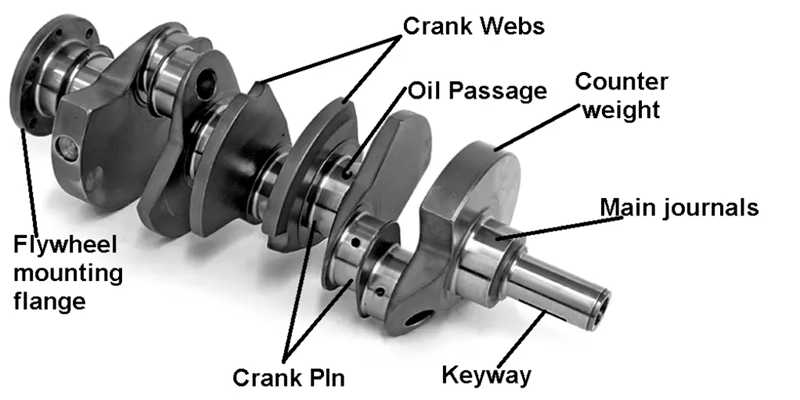

The “plane” in the word alludes to the crankshaft’s throws i.e. how the crankpins are arranged. Crankpins are the cylindrical extrusions on a crankshaft where big end of a connecting rod (conrod) is mounted. On the top of this conrod is a smaller end where a piston is attached via a wrist pin. As such, combustion pressure pushes down on the crown (top) of the piston, forcing the piston down. This motion is carried by conrod to push the crankshaft, making the later go around. The rotation of the crankshaft is what gives the engine its torque and power.

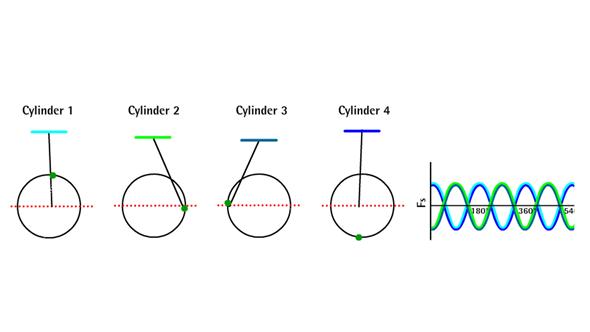

Traditionally, inline-four engines have their crankpins arranged in 180° intervals between them. In other words, piston one is up, the piston two is down, the following piston three is also down, and finally the last piston four is up. Seen from one end of the crankshaft, all the crankpins appear one a single plane (axis), hence the engine is known as a “flat plane.”

In accordance to this, the engine’s firing order (the order which a spark is introduced to ignite the fuel/air mixture) is every 180° of crank rotation i.e. 720°/4 cylinders = 180°. Why 720°? That is because a four-stroke engine requires two crankshaft rotations (720°) to complete the four strokes i.e. intake, compression, combustion, exhaust.

To illustrate this: Cylinder one fires, the crank turns 180°, cylinder three fires, the crank turns another 180°, cylinder four fires, and finally, cylinder two fires after another 180°. This is called an even firing order since it is 180°-180°-180°-180°.

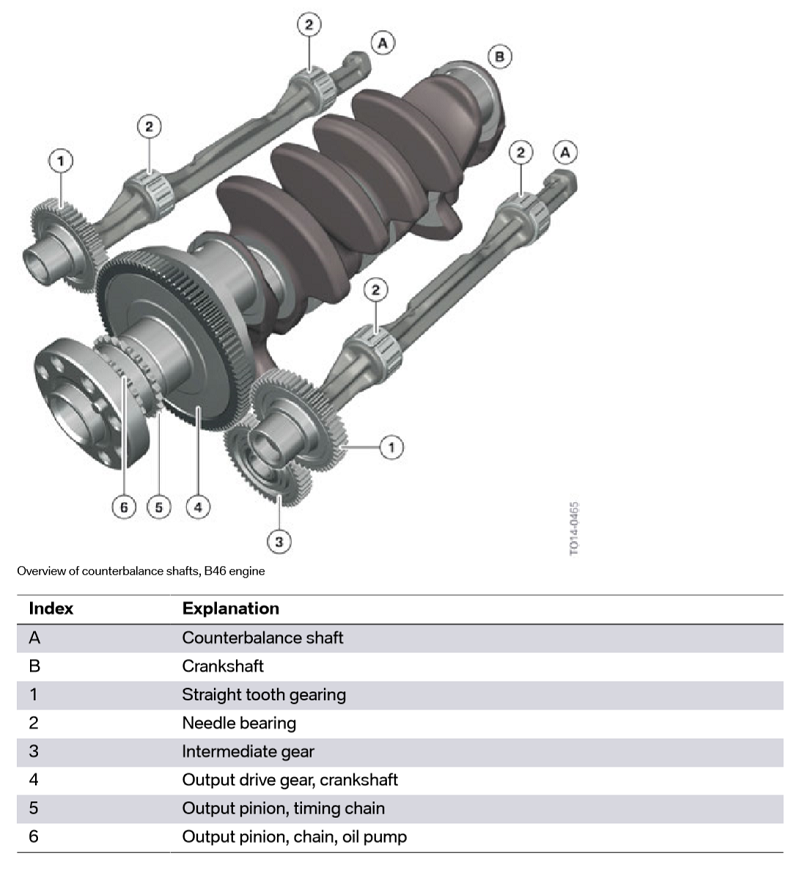

With this crankshaft structure all 4 pistons generate the secondary force in the same direction at the same time. 2 pistons move from TDC towards 90° and 2 other pistons move from BDC to 270°. It results in accumulating all the forces, because all forces are directed in one and the same direction. This is the total secondary force of this 180°crankshaft structure.

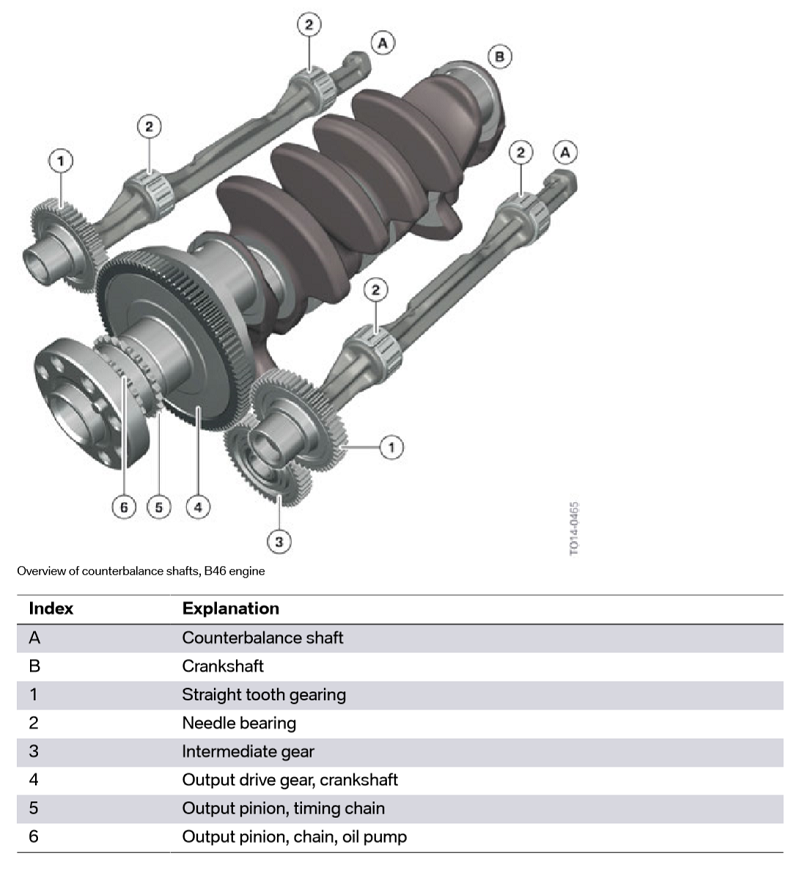

In other words, the inline-four engine has a lot of vibration but it only feels smooth because the shakes are quelled by a counterbalancer shaft.

Now the “crossplane engine”

The first crossplane crankshat/engine was actually first proposed in 1915, before Cadillac introduced the first crossplane V8 in 1923. V8 engines used flat-plane cranks prior to that.

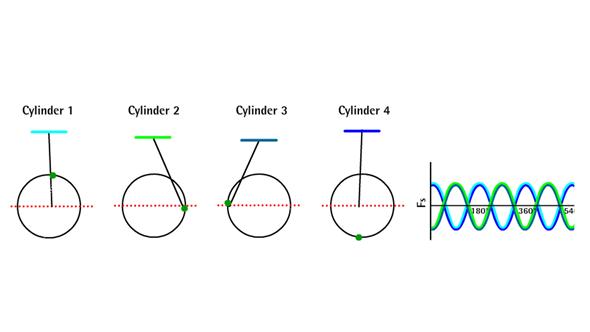

Now, since we have illustrated the flat-plane crank, the crossplane crank has its crankpins offset by 90°. This means, while crankpin one fully up, crankpin two is 90° away. The last crankpin is 180° from crankpin one, thus crankpin three is 90° away from crankpin four.

This arrangement would give the engine a 90°-90°-90°-90° firing order but(!) it results in a very wild power delivery like the traditional 500cc two-stroke (albeit V4) GP bikes. Mick Doohan called this the “Screamer” engine.

So, to quell that kind of character, the Big Bang firing order was introduced in the 1990 Honda NSR500, which crowded all the four cylinders’ firing order closer together, while leaving the crankshaft to turn the rest of the way without power pulses.

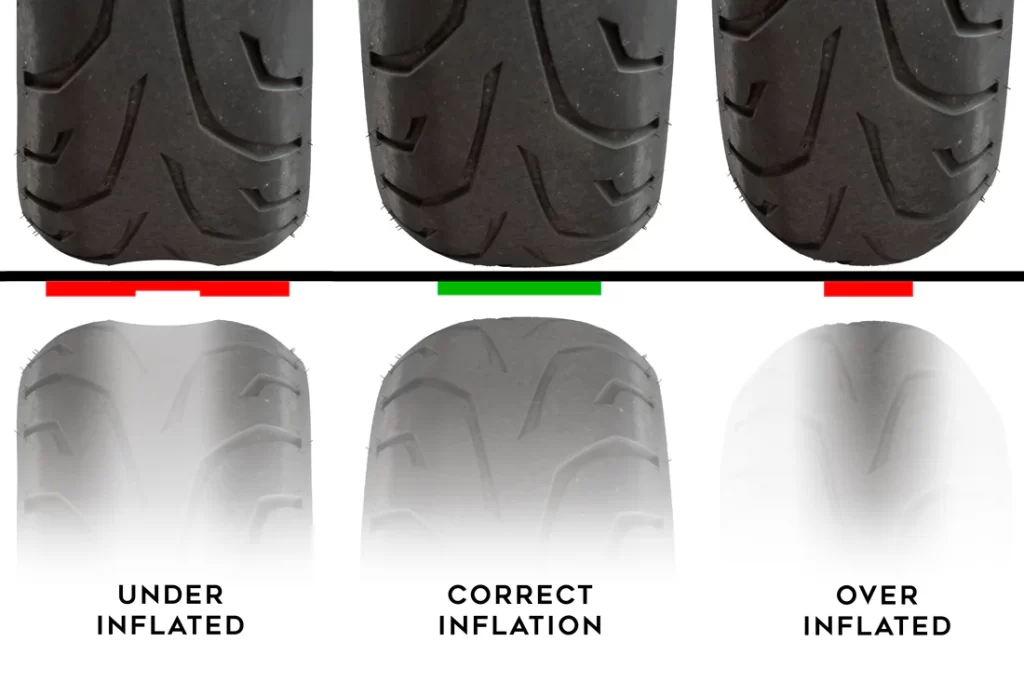

This is especially useful for high-powered motorcycles, because power pulses will disrupt the tyre’s grip. Each power pulse “kicks” the tyre and if the rear tyre starts to lose grip and spin, the power pulses will keep it spinning, hence losing grip. The rider has two choices here: Roll out of the throttle or end up having less acceleration off a corner, and even crash. In today’s world, traction control will interfere to cut the torque to the rear wheel causing the rider to lose acceleration off a corner.

On the other hand, having no power pulse lets the tyre “rest,” allowing it time to grip. Another advantage of this is better tyre life.

Moving forward to the Yamaha R1’s, its inline-four crossplane engine fires at 270°-180°-90°-180°. The firing order has also been changed to 1-3-2-4, instead of the flat-plane’s 1-3-4-2.

We have 4 pistons that are all in a different position from each other. Two pistons are at the beginning of moving downwards, and two pistons are at the beginning of moving upwards.

Piston 1 is at TDC and moves to 90°, while piston 4 is at BDC and moves to 270°. Both these pistons generate a force that is directed upwards (conrod outward movement), but piston 2 is at 270° and moves to TDC, while piston 3 is at 90° and moves to BDC. Both these pistons generate a force that is directed downwards (conrod inward movement).

This means that pistons 1 and 4 are a pair that have a force upwards and pistons 2 and 3 have a force directed downwards. As such, the upward forces are cancelled out by the downward forces. Ultimately, the crossplane crankshaft has no secondary force.

Benefits of the inline-four crossplane engine

With the crossplane crankshaft design, the inertia force (= inertia torque) is reduced to almost zero, apart from a little due to flex and torsion from the crankshaft. So what remains is the ‘pure’ combustion torque. The feeling of the combustion torque is what is meant by throttle feeling. The combustion torque is no longer overruled by the inertia torque with the crossplane crankshaft. This gives the rider the feeling he is directly controlling the rear wheel without any interference, thus improving the ride ability.

In addition to this is the irregular firing order which allows the rear tyre to rest as we mentioned earlier.

This was why Valentino Rossi chose the crossplane engined YZR-M1 when he joined the Yamaha MotoGP team in 2004. To him, it had a smoother throttle response and promoted better rear tyre traction. Remember this was when traction control and certainly aerodynamics were still decades away.

Yamaha then became the first manufacturer to adopt that crankshaft arrangement to a road bike, namely the YZF-R1 in 2009. It continues to be the only inline-four road bike with a crossplane crankshaft.

So, what about CP2 and CP3?

There are two types of parallel-twin crankshaft layouts, initially. Traditionally, the British twins used a 360° layout which the both pistons rose and fall together. Then, it was revised to the 180° twin, which one piston is at TDC while another is at BDC. But the former has a high secondary and primary vibrations, while the latter has high primary vibrations.

So, Yamaha first introduced the TRX850 in 1995 with a parallel-twin engine with a 270° crankshaft, to mimic the firing order of a 90° V-Twin’s.

But somehow, the TRX850 faded away. Not the engine layout, though, because Yamaha revived that format in the MT-07 in 2014, and called it the CP2 (crossplane 2-cylinder).

As for the CP3, as you may have guessed it, it is a three-cylinder engine with a crossplane crankshaft. However, it has to be said that the inline three-cylinder engine is already a crossplane engine, as the crankpins are spaced at 120° to each other rather than being on a flat-plane. It is just a matter of familial continue (and for marketing purposes) that Yamaha calls it the CP3.

So while the CP2 and CP3 are trademarks for Yamaha, the technology is not.