In an era marked by the anticipation of the internal combustion engine’s demise, Italian manufacturer Piaggio is breaking new ground in engine development.

- Despite the ongoing shift towards electric power, Piaggio is focusing on enhancing the efficiency of small, low-cost engines for scooters.

- The company’s latest innovation is a Variable Valve Timing (VVT) system designed specifically for these engines.

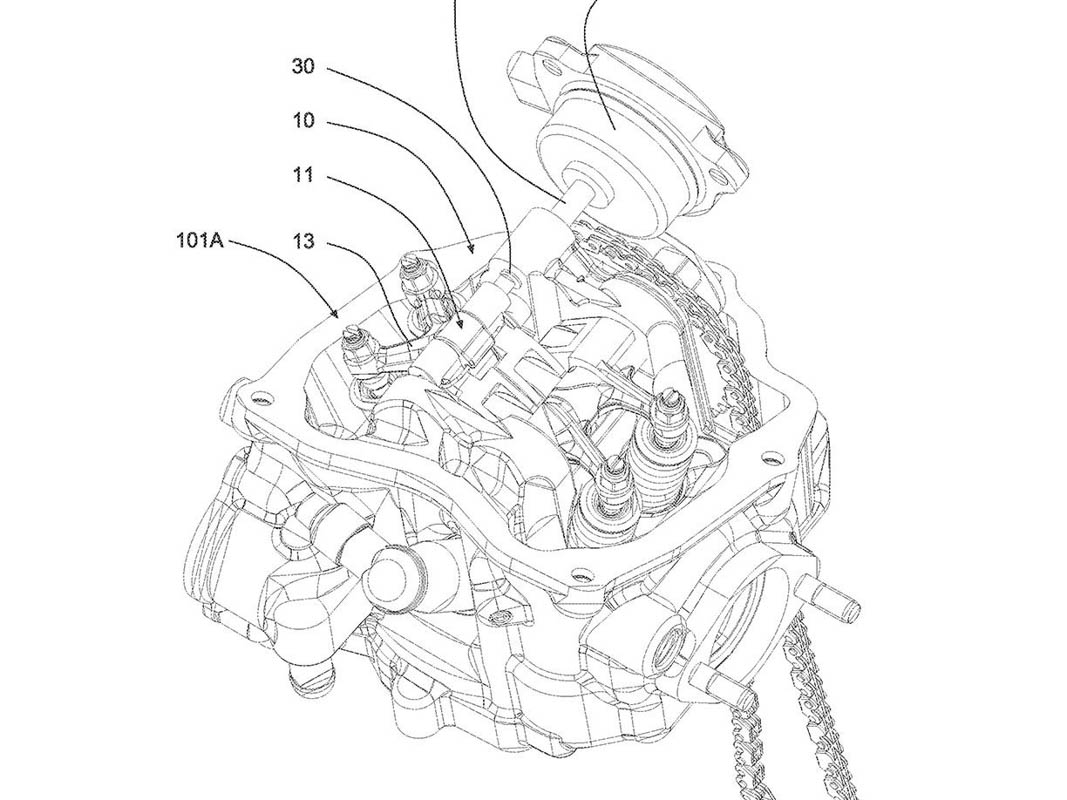

Piaggio’s VVT system, outlined in a detailed patent application, aims to optimise the intake timing on single-cylinder, single-overhead-camshaft engines used in scooters. Given the tight profit margins in this segment of the market, the design emphasises simplicity and reduced component count.

At first glance, Piaggio’s SOHC VVT system appears similar to Yamaha’s “VVA” (Variable Valve Actuation) design used in various motorcycles. However, a subtle yet crucial difference sets Piaggio’s system apart.

Both systems employ two profiles for the intake cam lobes, which act on a forked rocker arm to control two intake valves. Like Yamaha’s VVA, Piaggio’s system uses a pin to connect or disconnect the rocker arm, with an actuator to engage it and a spring to disengage it when not needed.

The key distinction lies in the number of elements in the rocker arm. Yamaha’s VVA system features two parts: one conventional rocker and one element for high-lift, long-duration cam lobes. In contrast, Piaggio’s design incorporates three elements in its rocker arm, allowing for more comprehensive control over valve timing, lift, and duration.

This innovation enables the Piaggio system to adjust not only valve lift but also timing, offering a distinct advantage over Yamaha’s system, which can only switch between low-lift, short-duration and high-lift, long-duration lobes. With Piaggio’s design, the high-rpm cam lobe can have different timing, enhancing engine performance at high revs.

The patent showcases this system on an engine that resembles the Vespa GTS 300, utilised in various Piaggio models, including the Piaggio MP3. Piaggio’s commitment to improving small-engine efficiency reflects its dedication to innovation in an ever-evolving industry.