A quick guide towards understanding what motorcycle chains are and how they work.

Typically, motorcycle chains come in either one of two forms – O-ring or X-ring tyres. Regardless of which, one that is worn out will either just sap power away at best or become dangerous at its worst.

Choosing the right chain depends on a bike’s power output and its weight. A chain needs to transmit the right amount of power to move the bike and a heavier motorcycle puts more strain on a chain.

Most litre-class sportsbikes now run a 530-pitch chain as standard for road use, but regular trackday riders might consider the narrower 520/525 width chain as not only does it save on weight, it absorbs less power, generates less friction and is slightly smaller, but won’t last as long.

A chain setup that’s too tight will accelerate wear through excess pressure on the sprocket teeth, chain joints and shaft bearings. A slack chain, on the other hand, will also quickly wear and in use could have a whip-like action that may result in it snapping off.

Either of these conditions will result in excessive chain elongation. This along with an increase in vibration and/or noise, will indicate when a chain is near the end of its life.

There are many factors which can affect chain wear, such as factory assembly accuracy, quality / condition / method of parts and lubrication. Even if you run a sealed roller chain, the best way to prolong its life is to clean it, externally lube it and perform proper regular adjustments.

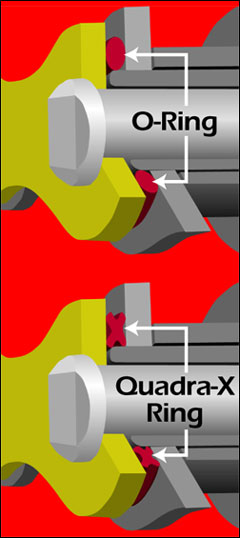

O-Ring Type

O-ring chains have small rubber O-ring seals that sit squashed between the pin link and the roller link plates, forming a barrier that holds factory-applied lubricant/grease inside of the rollers. These seals also prevent contaminants and dirt particles from entering inside the chain linkages and causing wear.

When the lubricant between the O-ring and the link plate disappears, the O-ring will wear and deteriorate. O-ring seals are usually made from a common synthetic rubber called acrylonitrile-butadiene, chosen because of its oil, fuel, heat and abrasion-resistant properties.

O-rings create friction that absorbs horsepower. The link plates that hold the O-rings are under compression, so more force is needed to articulate the chain – therefore, the transmitted power is decreased.

X-Ring Type

X-ring chains utilise an O-ring type construction that has an X-shaped cross-section. Its seals are flat-sided, so they have a greater contact patch with the sideplates. The X-ring’s four contact points create an extremely tight seal, keeping lubricant in and dirt out.

As a result, X-ring type seals have a lot less friction than O-ring seals because they do not have to be pressed as tight. This means the X-ring seals should last longer and retain lubrication within the chain for a longer time as well.

Top-spec race chains don’t have any O or X-ring seals to avoid loss of horsepower through friction. In racing, longevity isn’t an issue as the chains are constantly changed by race team mechanics.