Brake pads are the last thing that stops your vehicle, and keeps you from ramming the vehicle in front, or going off a cliff. Thus, its importance cannot be underemphasised.

But there are three main types of brake pads, namely sintered, ceramic, and organic. So let us take a look at the differences among all three, plus their pros and cons.

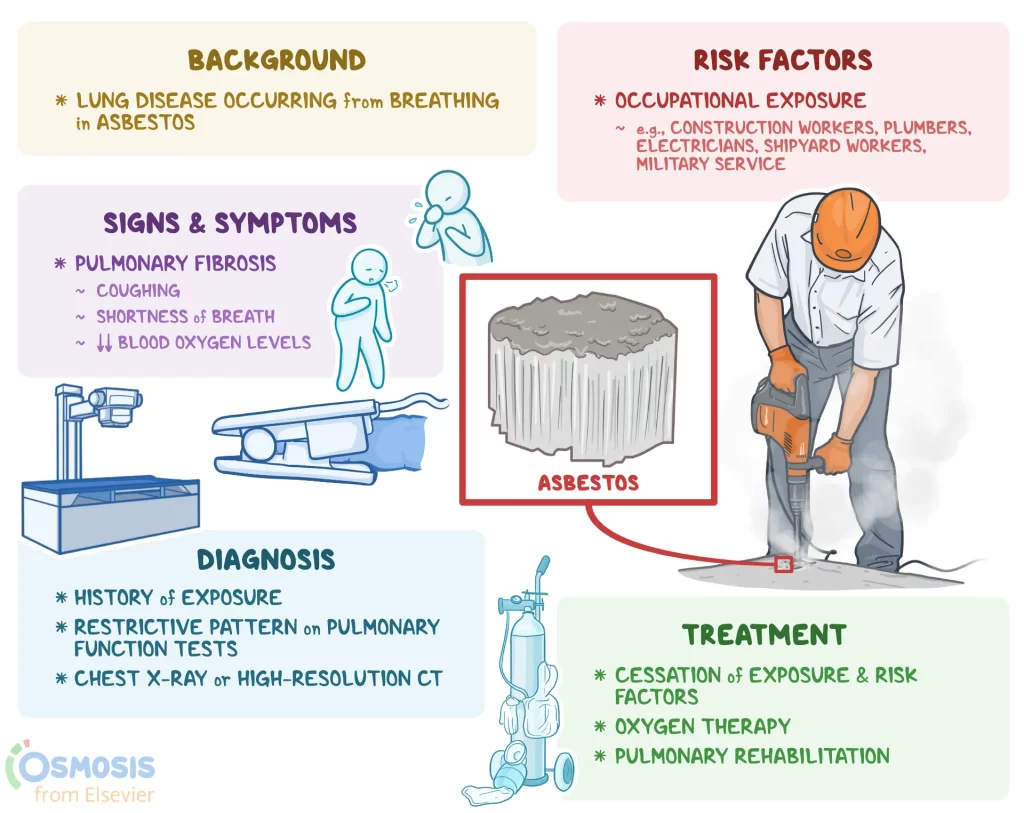

A word on asbestos

But first, a safety message. Asbestos was widely used in brake pads many years ago. There are six types of this mineral and their melting points range between 400° C to 1,040° C. It is also inflammable. As such, it became the natural material for brake pads. In fact, asbestos was also widely used in other sectors and products such as electrical insulation, lining for ceramic cookware, house insulation, even firefighting suits.

However, it was discovered in the 1970s that asbestos is toxic to humans and causes mesothelioma (a type of cancer that causes a thin lining of tissue over internal organs), asbestosis (long-term inflammation and scarring of the lungs), and lung cancer when the dust is inhaled. As such, the use of asbestos containing products has been banned in 66 countries.

However, Russia continues to be the biggest miner and exporter of the material (790,000 tonnes in 2020), and there are concerns of it being used in cheap aftermarket brake pads produced in India and China. So, DO NOT skimp on the cost of brake pads and use only those from reputable brands! Additionally, do not breathe in the dust when a mechanic sprays air onto your brake components to clean them.

On the other hand, Malaysia has banned five types of asbestos i.e. crocidolite, actinolite, anthophyllite, amosite, and tremolite, but allows chrysotile for “controlled use” in the private manufacturing sector, while banning it completely from public buildings including schools and hospitals.

Sintered/Metallic brake pads

These brake pads are made of copper, steel, iron and other metals mixed with a graphite binding component.

Pros:

- Metallic brake pads perform better than organic and ceramic brake pads in a wide range of temperatures.

- They also continue to perform well even under the heaviest rainstorms.

- They’re responsive and require minimal pressure on the pedal. The metal also withstands heat well.

- They are more resistant to wear, hence last longer.

Cons:

- Metallic brake pads are noisier than other types.

- They cause more wear on the brake discs.

- Metallic brakes are pricier than organic brake pads but more affordable than ceramic ones.

Organic brake pads

These contain the replacement materials for asbestos, known as non-asbestos organic (NOA). This mixed material is made of rubber, Kevlar, fibreglass and carbon compounds bound together with resin.

Pros:

- Organic brake pads are the least expensive on the market and recommended for normal driving.

- They generate enough friction to effectively stop the average vehicle yet do not produce as much heat as other pad materials.

Cons:

- Organic brake pads wear out more quickly than other types, which means you will have to replace them more often.

- They also do not work as well as ceramic and metallic pads in extreme temperatures.

- In addition, you have to apply a bit more pressure on the lever than you do with other types of brake pads.

Ceramic brake pads

These brake pads are made from a type of dense ceramic that has copper fibres in it in order to increase friction and conductivity.

Pros:

- Ceramic is the quietest brake pad material.

- Ceramic brake pads perform better than organic brakes in a range of temperatures.

- They last long but has less wear on steel brake discs compared to sintered pads.

Cons:

- Ceramic brake pads are pricier than other types.

- Plus, they underperform in extreme cold.

- In addition, ceramic does not absorb as much heat as other materials.

What is missing here?

You would probably notice there is mention of carbon brake pads. Well, truth is, carbon brake pads for road use is not 100% carbon, but are of mixed materials so you would find sintered-carbon or carbon-ceramic brake pads.

True carbon brake pads are only used in the highest echelons of racing i.e. MotoGP and Formula 1.

A word about copper

More and more manufacturers are switching away from having copper fibres in ceramic and all other types of brake pads as brake dust containing copper had been found to pollute the environment, especially in waterways.

SBS is one manufacturer who are doing so and their copper-free brake pads are marked as “Better Brakes.”